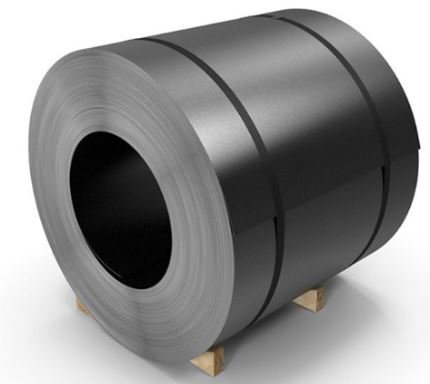

With over three decades of proven industry expertise, National Steel Traders has established itself as a trusted and reputable supplier of both prime steel products and ferrous/non‑ferrous scrap. Our comprehensive portfolio encompasses HR, HR Plate, HRPO, CRFH, CRHSL, CRCA, GPSP, GA, GL, and PPGI materials, all supported by advanced slitting, cut‑to‑length, and shearing facilities that ensure precision and consistency in processing.

Strengthened by enduring partnerships with leading steel manufacturers, a monthly handling capacity exceeding 5,000 MT, and strategically located warehouses integrated with a robust logistics network, we are equipped to deliver reliable, large‑scale supply without compromise on quality or timeliness.

Guided by a philosophy of value creation across the supply chain, we remain committed to fostering long‑term, mutually beneficial relationships with both suppliers and clients. This unwavering dedication to excellence has positioned National Steel Traders as a distinguished and dependable partner in the domains of prime steel distribution and scrap trading.