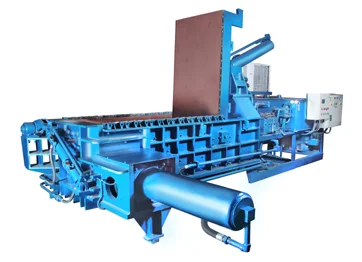

At National Steel Traders, baling is the process of compressing loose metal scrap into dense, manageable blocks (bales) using hydraulic triple action baling machines. This advanced process reduces the volume of scrap by up to 80%, making storage, handling, and transportation far more efficient. Our triple action balers manufacture high-density metal bales in sizes ranging from 8" x 8" to 12" x 12", with weights between 20 kg to 100 kg, depending on the type and quantity of scrap fed into the system. Beyond space savings, baling delivers multiple advantages:logistics efficiency by lowering transport costs and maximizing container/truck loads; melting efficiency through improved furnace charging, reduced oxidation, and higher yield; quality control by ensuring uniform scrap size for consistent recycling operations; and a positive environmental impact by minimizing scrap spillage, dust, and enhancing workplace safety. With five triple action baling machines currently in operation and plans to add more, NST is committed to boosting production capacity and delivering reliable, high-quality scrap solutions to meet the growing demands of India’s recycling and manufacturing industries.

Baling Process

“Efficient. Compact. Sustainable – the power of baling.”

Partner with us and let your steel shine brighter

Contact us for any steel related inquiry